Welding and non-destructive testing (NDT) of composite materials

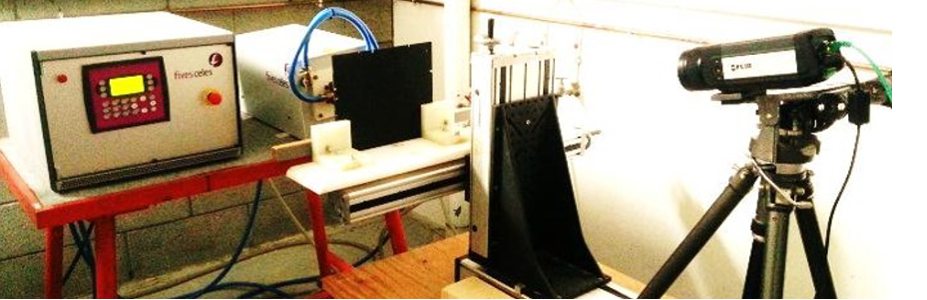

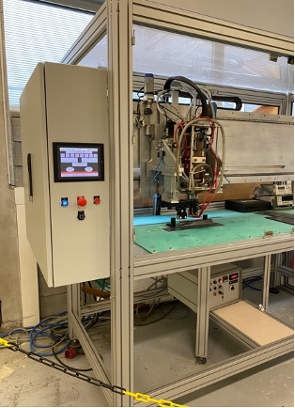

Inducto-thermal NDT bench

IREENA has developed fine models for non-destructive testing of carbon fibre composite materials using the inducto-thermal technique. This work was based on experimental validations carried out thanks to this bench, which is composed of several induction generators in order to have a wide range of test frequencies and a thermal camera with 50 Hz mapping.

Inducto-thermal NDT bench

Inducto-thermal NDT bench

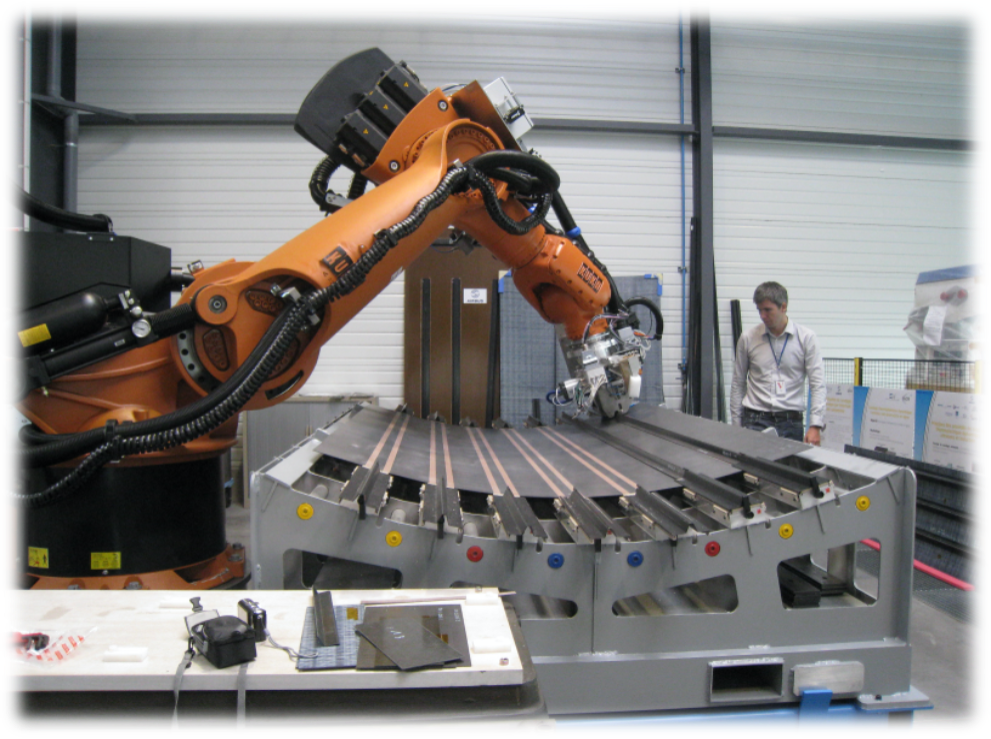

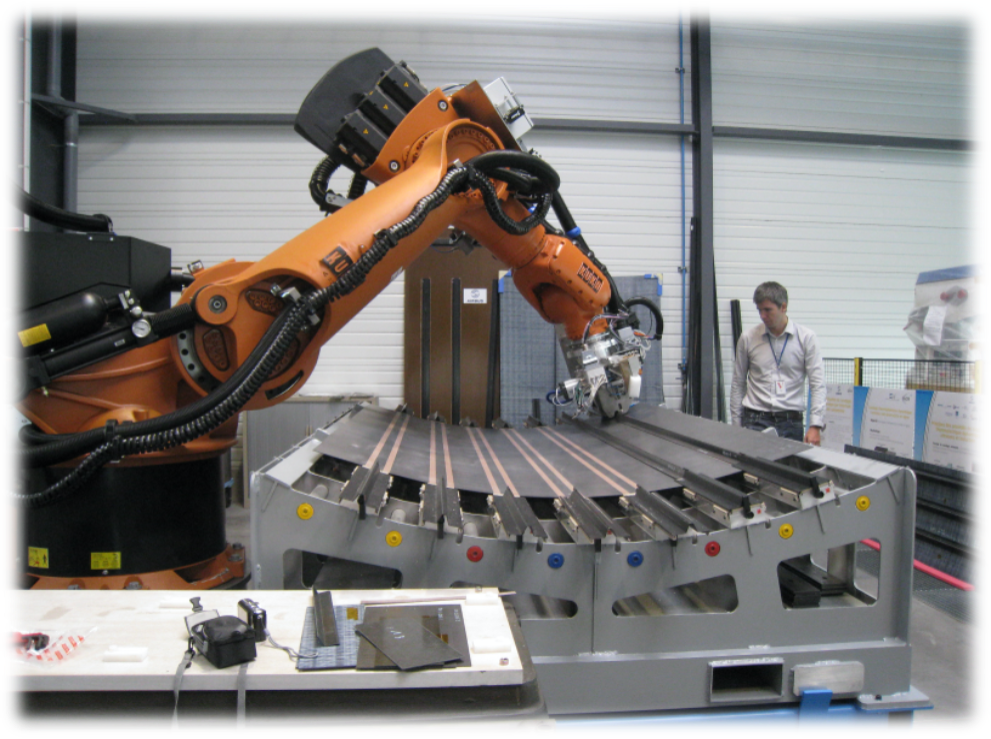

Induction welding bench

As part of the development of the induction welding activity for thermoplastic composites, two benches are currently developed/used by IREENA. The first 1D bench is an instrumented R&D bench (HF current probe, thermocouple or optical fibre to measure temperature, IR camera, etc.) with a high scanning capacity of the generator frequency. This 1D bench allows the development of processes on elementary parts and the validation of our codes and calculation hypotheses. During the 2017-2020 period, a new pre-industrial 3D bench on the IRT Jules Verne site (Sideffect project) was developed and is now operational, enabling the process to be validated for more complex parts (aircraft fuselage type). The entire design of the inductive chain of this new 3D bench was piloted by IREENA, which will be able to operate this bench after the end of the project.

3D induction welding bench, Airbus site (MP16 project)

|

|

| 1D induction welding bench, IREENA site | 3D induction welding bench, IRT Jules Verne site (Side Effect project) |

3D induction welding bench, Airbus site (MP16 project)

IREENA's equipment and platforms were partly co-financed by the European Regional Development Fund (ERDF).

Cofunding

IREENA's equipment and platforms were partly co-financed by the European Regional Development Fund (ERDF).

Unit Director

Head of TRU 1

Head of TRU 2

Head of TRU 3

Mis à jour le 06 April 2023.